Shanara Veivers

Diversity and hard work paves the path for a rewarding career in horticulture.

It’s not every day you find a job that sees you out and about doing field work, running lab experiments, organising and facilitating events, and visiting banana growers on farm. This is all in a day’s work for Research Horticulturist Shanara Veivers, who has gained a diverse range of experience since starting with the Department approximately four years ago.

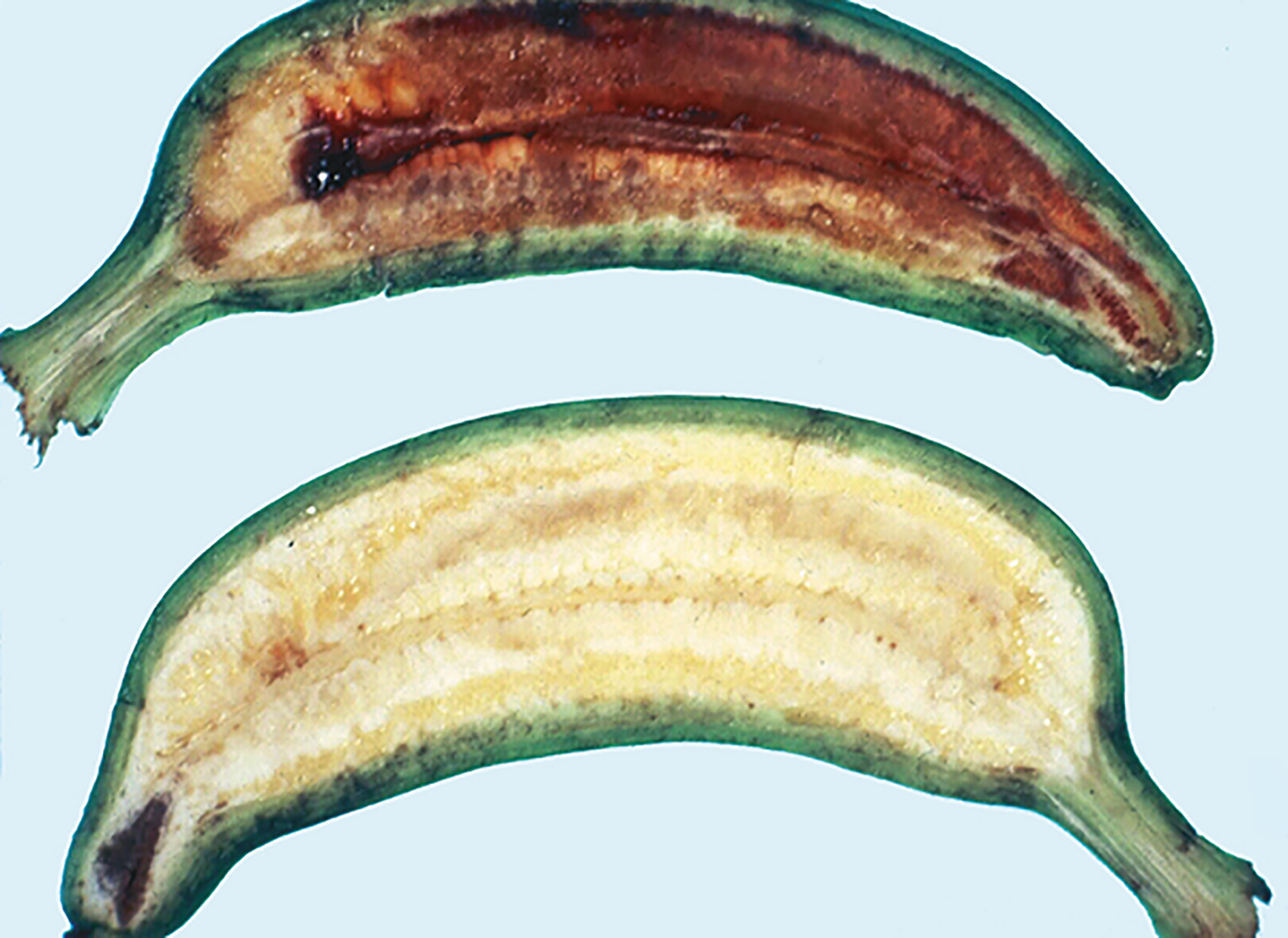

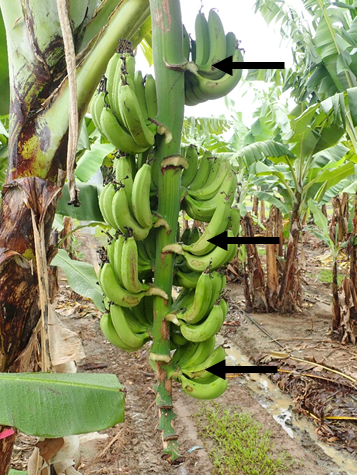

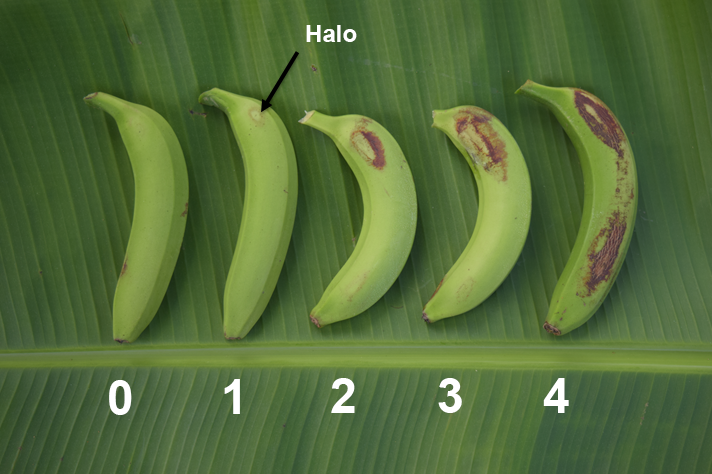

As an integral member of the banana extension team, Shanara has been responsible for managing an innovation trial based at the South Johnstone Research Facility. This has involved investigating a number of ‘out of the box’ concepts focused on increasing agronomic and environmental performance of banana farming systems. Some of her research areas have included the effects of different de-suckering methods, ground covers, ‘softer’ chemical options, and more recently the use of entomopathogenic nematodes for the control of banana weevil borer and bunch pests.

Shanara Veivers

Research Horticulturist

Department of Agriculture and Fisheries

Ecosciences Precinct

Brisbane