Results from the Subtropical packed product analysis

Minor defects

There was a far greater number of minor defects than major defects found as part of the Subtropical packed product analysis. Results showed that of the 709 clusters, 235 or 31.15% had a minor defect. This is again over Woolworths specifications requiring no more than 10% of clusters with minor defects per consignment.

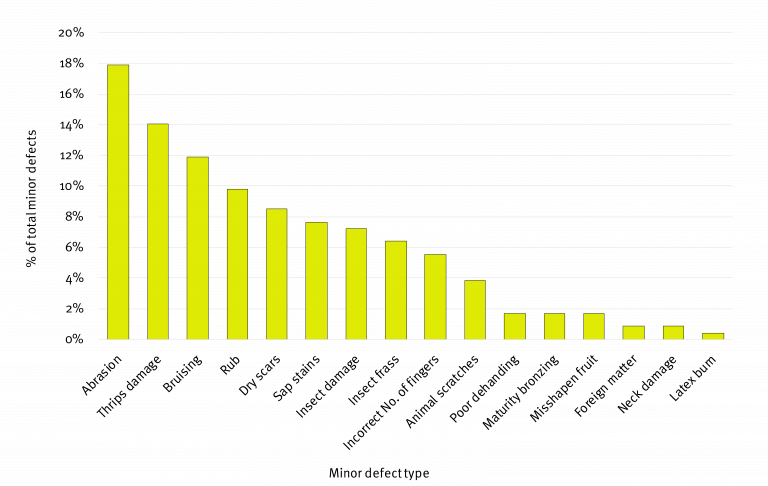

The figure below shows 16 minor defects found in the study and lists them from the most common on the left through to less common on the right.

The six most common minor defects which accounted for almost 70% of clusters included, abrasion, thrips damage, bruising, damage caused by rub, dry scars and sap stains.

Broadly speaking these minor defects can be addressed through altering in-crop management and handling practices, early identification of pests and establishing effective control methods and post-harvest handling and packing procedures.

Abrasion and rub

Dry, brown and calloused to fresh, wet appearing, black patches on the peel. Caused by rubbing of bract, flower tip, leaf, bag or adjacent fruit against the peel or poor post-harvest handling.

Abrasion and rub damage to fruit was the most common minor defect identified during the study. An accurate assessment of the reasons for abrasion and rub damage in your paddock will help guide which strategies are appropriate to reducing its impact.

Thrips damage

The damage caused by Flower and Rust Thrips can be significant. It was the second most common minor defect found during the packed product analysis. Effective management of these pests is possible through consistent crop monitoring and putting in place effective control strategies.

Bruising

Occurs when enough impact or compression forces are applied to fruit. Appears as a flat, sunken or partially broken area of peel which will darken and become increasingly obvious as fruit ripens.

Bruising proved to be a very common minor defect identified in this study and can be reduced by evaluating and adapting post-harvest handling strategies and equipment.

There are a broad range of reasons why physical damage may occur to bunches, such as abrasion, bruising, rub and dry scars. Some of these may be easily avoided and there are others that cannot be prevented. Rub, abrasion and dry scars caused by wind are not easily preventable. However, the use of clips-slips can be used to improve fruit quality, by placing between hands to reduce abrasion and rub of the bract, flower tip or adjacent fruit against the peel. Undertaking a cost-benefit analysis on the use of clips-slips may be a worthy exercise for the subtropical banana industry, as higher prices for blemish free fruit may very well outweigh the cost of use.

Post-harvest handling is one area where small changes to equipment, techniques or practices can have large impacts on fruit quality. Changes to post-harvest handling on your farm should be investigated to determine whether small, cost-effective changes can be easily implemented to help decrease defects, increasing quality and ultimately profitability.

Thrips damage was the second most common minor defect found in this study and included damage from rust thrips and flower thrips, including corky scab. Effective management of these pests is possible through consistent crop monitoring and putting in place effective control strategies. Monitoring and control strategies for thrips species vary and should be tailored to your specific conditions before being applied on-farm.

Sap stains are another minor defect that can be easily addressed with changes to post-harvest handling techniques and equipment. Packing too quickly, allowing de-handed clusters to sit for too long, failing to wash fruit in a trough and a lack of paper/plastic sheets between fruit in cartons are a few factors that can increase the likelihood of sap stains. These can be addressed simply by training fruit packers or making changes to equipment and packing processes. Watch the ‘Developing a standard industry banana carton’ video for some handy information on best practice packing standards.

*Fruit in this study was assessed against the most recently released Woolworths subtropical Cavendish produce specifications, issued 9 December 2014. Always make sure you’re referring to the latest specifications relevant to your business.

More information...

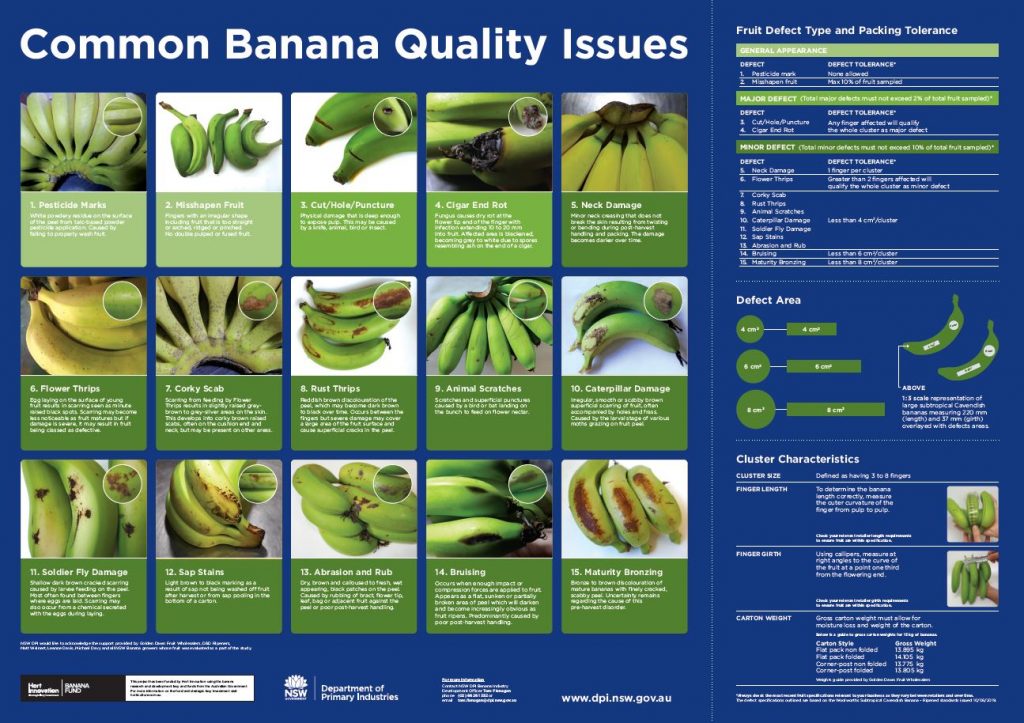

A poster is now available showing common quality issues and packing guidelines for subtropical banana growers. To receive a hard copy or for more information contact NSW DPI Industry Development Officer Tom Flanagan on (02) 6626 1352 or email tom.flanagan@dpi.nsw.gov.au

NSW DPI would like to acknowledge all growers who agreed to participate in the study, Matt Weinert, Leanne Davis from NSW DPI and Valerie Shrubb, Anastasia Van Blommestein and Brett Renton from WA DPIRD for undertaking the research.

This research has been funded as part of the Subtropical Banana Development and Extension Program (BA16007), which is funded by Hort Innovation, using the banana research and development levy and co-investment from the New South Wales Department of Primary Industries and WA Department of Primary Industries and Regional Development. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture.