Disinfectants prove to be an integral part of on-farm biosecurity

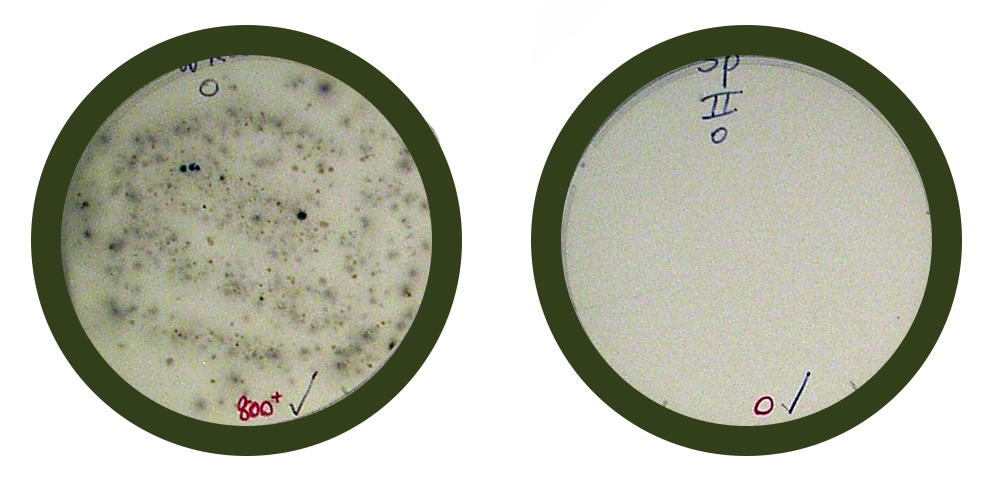

Using disinfectants as part of your cleaning regime is vital to minimise the spread of Panama disease. Research shows that various disinfectant products are effective in killing fungal spores that cause Panama disease.

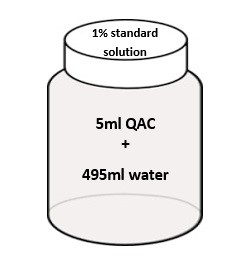

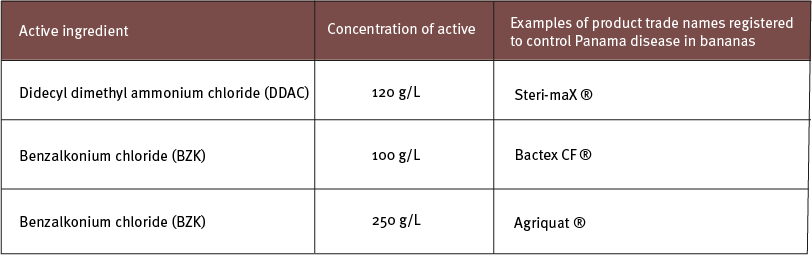

Products listed in the table below are examples of disinfectant products which were shown to be effective when applied at 1% solution.

Remember...

Before using any chemicals always check the current registration status and read the product label. A minor use permit is available for banana growers to use these products off-label (PER 86485) http://permits.apvma.gov.au/PER86485.pdf. Label and permit details can be accessed via APVMA website: www.apvma.gov.au

It is important to note that soil reduces the effectiveness of disinfectants. Different soil types have varying impacts on the effectiveness of the products. However, research has shown that once the equivalent of 1g of soil is present in 20mL of solution (1% product) then the effectiveness of products is compromised or reduced.

Investigations into DDAC products (e.g. Steri-maX®, Path-X™, Sporekill® made at 1% solution) has found that when there is no soil contamination, these products remain effective as a disinfectant after being exposed to sunlight, temperature and humidity for up to 12 months.

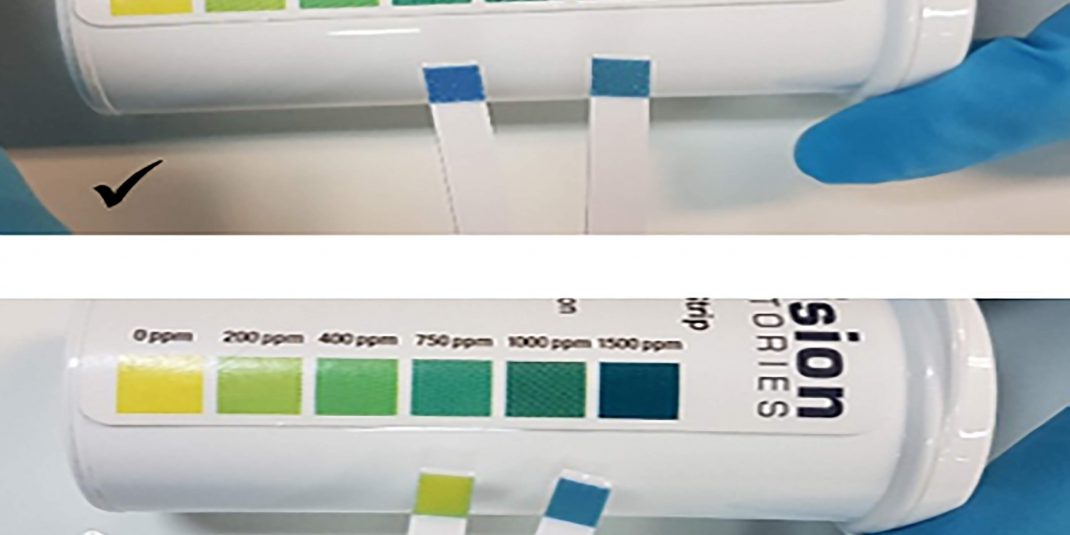

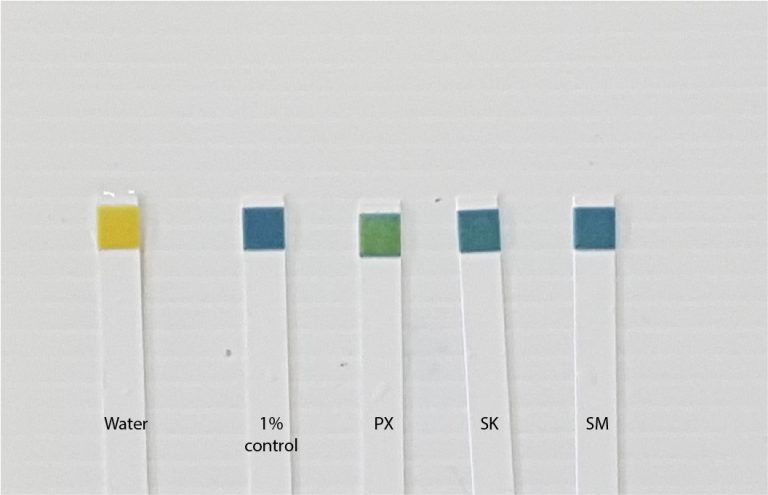

Quaternary ammonium compound test strips have shown to be an effective tool that measures the concentration of the active ingredient DDAC or BZK in disinfectant products. These easy-to-use test strips do not require dilution of the sample and are used by comparing the colour development on the test strip to the colour scale.

In summary:

- DDAC and BZK disinfectant products used at the correct concentration and as per label or permit specifications (contact times) do kill the fungal spores that cause Panama disease.

- It is important to remove all soil and organic matter before applying any disinfectant product and replace solutions if they become contaminated.

- Easy-to-use test strips can be used to regularly test solutions in footbaths, spray shuttles and wash-down facilities.

More info...

Remember: Always follow and adhere to product label rates and instructions. Label and permit details can be accessed via APVMA website: www.apvma.gov.au

This research was funded as part of project BA14013 Fusarium wilt Tropical Race 4 – Biosecurity and sustainable practices which was funded by Hort Innovation, using the Banana research and development levy, co-investment from the Queensland Department of Agriculture and Fisheries and contributions from the Australian Government. Hort Innovation is the grower-owned not-for-profit research and development corporation for Australian Horticulture.