Subtropical banana soil and leaf interpretation guidelines

Plant nutrition for subtropical banana production

In order to maximise banana productivity and yield, whilst increasing resilience to pests and diseases, it is necessary to get plant nutrition right. Soil and tissue analyses are vital for monitoring soil fertility and plant nutrition. Regularly testing soil and tissue nutrients, and tracking changes in nutrient over time, is essential for developing an accurate and appropriate fertiliser program that delivers the nutrients needed at the right time and can result in efficient and sustainable fertiliser use. It also allows soil fertility issues to be identified early and provides an opportunity to correct them before they begin to affect productivity. It is not possible to achieve this without correctly interpreting the information gained from soil and tissue nutrient analyses. However, the results reported from soil and tissue analyses can often be confusing and include irrelevant information, making their interpretation challenging. The NSW soil and leaf analysis interpretation guidelines for bananas has been developed to assist with the interpretation of soil and tissue tests so you can make sure your bananas are getting the nutrient they need.

In order to maximise banana productivity and yield, whilst increasing resilience to pests and diseases, it is necessary to get plant nutrition right. Soil and tissue analyses are vital for monitoring soil fertility and plant nutrition. Regularly testing soil and tissue nutrients, and tracking changes in nutrient over time, is essential for developing an accurate and appropriate fertiliser program that delivers the nutrients needed at the right time and can result in efficient and sustainable fertiliser use. It also allows soil fertility issues to be identified early and provides an opportunity to correct them before they begin to affect productivity. It is not possible to achieve this without correctly interpreting the information gained from soil and tissue nutrient analyses. However, the results reported from soil and tissue analyses can often be confusing and include irrelevant information, making their interpretation challenging. The NSW soil and leaf analysis interpretation guidelines for bananas has been developed to assist with the interpretation of soil and tissue tests so you can make sure your bananas are getting the nutrient they need.

Download a copy of the guidelines and other resources

For more information contact:

The Better Bananas team

NSW Department of Primary Industries – Industry Development Officer, Tom Flanagan – 02 6626 1352

Department of Agriculture and Fisheries – Banana Extension Team, South Johnstone – 07 4220 4177

or email the team at: betterbananas@daf.qld.gov.au

The NSW soil and leaf analysis interpretation guidelines was funded by the New South Wales Department of Primary Industries.

Banana rust thrips – monitoring and control

Banana rust thrips Chaetanaphothrips signipennis

Monitoring and control options

Monitoring

Rust thrips can occur on unbunched plants and their presence can easily be determined by monitoring established plantations fortnightly throughout the year. New plantings should be inspected prior to bunching in order to determine both the presence and severity of rust thrips infestations so that control measures, if required, can be carried out before fruit damage occurs.

Under heavy infestations, rust thrips can produce characteristic V-shaped rust-coloured markings on pseudostems (Figure 1) as a result of their feeding where the leaf petiole meets the pseudostem. If these markings are observed, the presence of thrips should be confirmed by gently pulling the leaf petioles away from the stem (Figure 2) and inspecting these sites with a 10x hand lens. In addition, it’s advisable to occasionally lift a number of bunch covers and inspect the developing fruit to ensure no thrips or damage are present. If damage has occurred, further damage can be prevented by additional insecticide application, taking care to comply with withholding periods in accordance with the label.

Damage to fingers can range from faint smudge-like markings through to the characteristic slightly red/brown damage known as ‘rust’. Special attention should be paid to those fingers which are closely pressed together as this is where the thrips prefer to feed and shelter.

Control options

Chemical

Chemical control can be directed at both the soil-dwelling pupal stage as well as the adults and larvae on the fruit and plant. Please ensure to always check the Australian Pesticides and Veterinary Medicines Authority (APVMA) website to confirm registration of chemical products before use.

Soil/plant treatments: Apply registered insecticide (e.g. bifenthrin, imidacloprid) as per label directions (e.g. pseudostem treatment, band treatment method). Ensure ground treatments achieve good cover of both the ground around the base of the pseudostem and up the base of the pseudostem as per the label. Treatments aimed at banana weevil borer that are applied to the soil or pseudostem will also provide temporary control of rust thrips. Treatments applied in September/October for weevil borer should provide partial protection, depending on the product used, during November/December and into the early part of the following year.

Fruit treatments: Bell injection is an important component of rust thrips control on the bunch. Correct and timely application is vital for effective control. Apply a registered insecticide (e.g. acephate, spinetoram) as per label or permit directions to the bell in an upright vertical position. Ensure the injector is calibrated and used correctly.

Bunch spraying/dusting at bagging is also an important measure to control rust thrips. Apply a registered insecticide (e.g. chlorpyrifos, spinetoram) as per label or permit directions to the bunch. Ensure the bunch spray/duster is calibrated and used correctly. Bifenthrin impregnated bunch covers can also be used instead of applying insecticides to the bunch as dusts or sprays.

Insecticide resistance can compromise the effectiveness of insecticides, therefore adhering to the label and or permit directions is essential. Endeavour to use chemicals with differing modes of action to minimise the possibility of resistance developing.

Monitoring is important to assess that the applied treatment has been effective.

Cultural

Intact bunch covers (which cover the full length of the bunch) do provide some protection if applied very early. These cannot be relied upon to fully protect the fruit, particularly during severe infestations. Regular checking of fruit under the bunch covers is essential to ensure that damage is not occurring. Ensure treatments are applied immediately after detection to prevent further damage.

Biological

There are currently no specific predators identified which provide a commercial level of control. General predators such as lacewings and ladybird beetles may exert some control of rust thrips on the plant, and ants may be effective in removing some of the pupae in the soil.

For more information contact:

The Better Bananas team

Department of Agriculture and Fisheries

South Johnstone

07 4220 4177 or email betterbananas@daf.qld.gov.au

This information is adapted from: Pinese, B., Piper. R 1994, Bananas insect and mite management, Department of Primary Industries, Queensland

This information has been updated as part of the National Banana Development and Extension Program (BA19004) which is funded by Hort Innovation, using the banana industry research and development levies and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. The Queensland Government has also co-funded the project through the Department of Agriculture and Fisheries.

Banana rust thrips – general information

Banana rust thrips Chaetanaphothrips signipennis General information

Occurrence

Banana rust thrips is a serious and frequent pest of bananas and has been since they were first grown in Queensland. Damage occurs in all areas but is more severe in bananas grown in well-drained red soils.

Seasonality

Rust thrips can damage fruit throughout the year however, the period from November to April is the period of greatest activity. Experience has shown that unusually dry periods during November and April encourage heavy build-ups of thrips and subsequent damage. Wet conditions are thought likely to cause high mortality of the soil-dwelling pupal stage, either directly from drowning or by encouraging the development and spread of diseases.

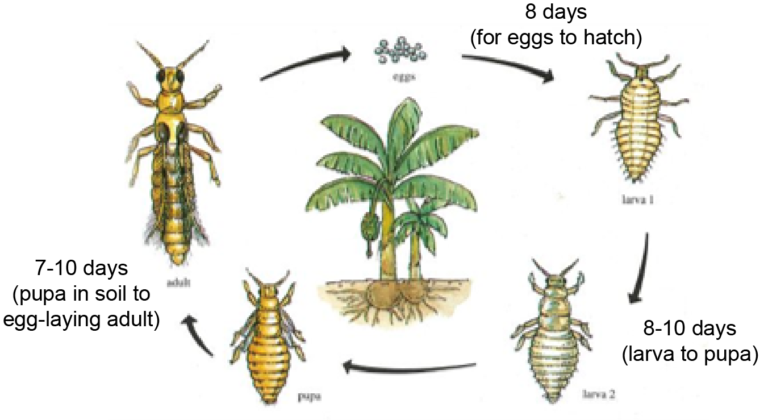

Description and life cycle

The extremely small eggs are inserted by the female just below the surface of the fruit or other plant tissues. The small (0.5–1.0 mm long) white, slender larvae do not have wings and can be seen moving when areas of infestation are exposed by separating touching fruit. Larvae can also be seen moving on the stem of the plant by pulling back the edge of leaf sheaths. When fully developed, the larvae drop to the ground and pupate just below the soil surface, approximately 30 cm from the base of the plant and suckers. The white pupa is about 1mm long and can be very difficult to find.

The adult has small feather-like wings and is a slender (1–1.5 mm) straw-coloured insect. The wings are fringed with a line of dark scales and, when at rest along the body, these scales form a characteristic black longitudinal line running the length of the abdomen. Two eye-like dark patches at the base of the wings are a characteristic of rust thrips adults. These patches help distinguish them from the smaller males of banana flower thrips.

Damage

Fruit damage is caused during feeding by the larval and adult stages of the thrips. The damage first appears as a faint smudge-like mark (Figure 3) between the fingers in the area where two adjacent fingers touch (Figure 4). This later develops into typical reddish-brown ‘rust’ areas. Severe damage can result in skin cracking (Figures 5 & 6).

The superficial damage does not reduce the fruit eating quality. However, affected fruit can be downgraded or rejected, depending on the severity of damage and the current market supply conditions.

Note: Rust thrips damage should not be confused with maturity bronzing, which produces a rusty, reddish discolouration on the fingers. While it appears similar to rust thrips damage, maturity bronzing occurs on the exposed outer curve of the fruit and is not confined to areas where fingers are touching.

For more information contact:

The Better Bananas team

Department of Agriculture and Fisheries

South Johnstone

07 4220 4177 or email betterbananas@daf.qld.gov.au

This information is adapted from: Pinese, B., Piper. R 1994, Bananas insect and mite management, Department of Primary Industries, Queensland

This information has been updated as part of the National Banana Development and Extension Program (BA19004) which is funded by Hort Innovation, using the banana industry research and development levies and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. The Queensland Government has also co-funded the project through the Department of Agriculture and Fisheries.

Banana rust thrips

Rust thrips – a persistent and pesky pest!

Rust thrips, a tiny pest that can lead to large economic losses, is consistently popping up as a priority pest for banana growers. This is the feedback the banana extension team has been given by growers at recent farm visits. The team is continuing to gain valuable information from growers on issues affecting fruit yield and quality. Discussions so far have highlighted some commonalities across farms, with Rust thrips being raised as the most common issue amongst growers.

What exactly is it though, that makes Rust thrips such a headache for growers? To help answer this, the extension team asked growers and consultants at the 2020 roadshows to share their experience with managing the pest. Here’s what was learnt.

Most growers who attended the roadshows said that they were reasonably satisfied with the level of control they were getting. However, they weren’t happy with the way in which they must achieve it.

Rust thrips is a persistent pest of bananas, and management practices to control it are on-going and must be undertaken in a timely manner. If not adequately managed, the damage can very quickly become severe and economic losses high. Growers agreed that timely application of chemicals is critical, using the example of bell injection and the need to ensure chemical is injected in the correct position when the bell is still upright. Some growers expressed it wasn’t always easy to be on top of everything that needs to be done, especially given the current labour shortages within industry. Unfortunately, the consequences for growers falling behind in managing this unrelenting pest are almost always high levels of damage to fruit that doesn’t meet market specifications.

Concern was also raised that the current control methods rely too heavily on chemicals, with an over-reliance on their use, with some growers stating they would like to see industry move to alternative softer/biological control options. Workplace health and safety issues surrounding chemical application was also raised, reinforcing the desire to move towards softer biological options. Some growers also indicated their chemical control was no longer effective, suspecting chemical resistance has developed. Rust thrips’ fast life cycle and their relatively sedentary population means they can quickly build resistance to chemicals. This feedback serves as an important reminder for growers to rotate chemical groups as part of their bunch pest management to minimise the risk of chemical resistance.

So where to from here? Project activities included in the project Improved Plant Protection for the Banana Industry (BA16001) include evaluating new chemistries and biological products for bunch pest management. The latest screening of new chemistries, including biological products used for bell injection, commenced in early 2021. Chemical companies will be encouraged to seek registration on any products that perform well in these trials. As part of an Integrated Pest Management (IPM) approach, the project has also investigated cultural controls for Rust thrips. Bunch cover trials have shown that damage levels varied between different coloured bunch covers. Orange covers had significantly higher level of thrips damage compared to all other colours. White covers had the lowest levels of damage. Read more on the bunch cover trials.

While researchers continue to investigate new alternative management strategies for rust thrips, it’s encouraged that growers familiarize themselves with this pest and the current monitoring and control recommendations.

Keep an eye out on the home page for updates on bunch pest research.

Click for more information

This information has been prepared as part of the National Banana Development and Extension Program (BA19004) which is funded by Hort Innovation, using the banana industry research and development levies and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. The Queensland Government has also co-funded the project through the Department of Agriculture and Fisheries.

NextGen—planting the seed for succession

NextGen—planting the seed for succession

When is the right time to start the conversation about farm succession and passing on the reins to the next generation?

Far North Queensland NextGen growers met for the first time in 2021, with succession planning being a key agenda item. With many growers coming from a family farming history, succession planning can be tricky in navigating the needs and wants of family members at different ages and stages of life, with different motivations.

Guest speakers Nick Birchley and Alison Larard shared their knowledge and experiences on farming succession with the group. Nick, a Financial Councillor for the Rural Financial Counselling Service has extensive agricultural counselling experience and offers financial counselling to banana growers. Coming from a farming background, Alison is a Senior Beef Extension officer for the Department of Agriculture and Fisheries and a 2018 Nuffield Scholar, completing her scholarship in Succession Planning and Business Management. Stepping through the process of succession, Nick and Alison shared their experiences with the group on what farm business succession is, when to start planning, the stages of a business’s life cycle and how the Rural Financial Counselling Service can assist banana growers with succession and financial counselling.

The group also discussed the need for labour saving technologies, with a discussion on agricultural compliance management software available to assist growers with compliance, digital record keeping and audits. As an example, insight into an up and coming system to help with record keeping for compliance management was given by Jennifer McKee from Growers Support.

If you would like further information on how your business can prepare for succession please contact Nick Birchley (RFCS) via email nick@rfcsnq.com.au or phone 0448 460 309. If you are interested in getting involved in NextGen get in touch with Tegan Kukulies (DAF) – tegan.kukulies@daf.qld.gov.au or 0459 846 053.

The NextGen initiative is part of the National Banana Development and Extension Program (BA19004). This project has been funded by Hort Innovation, using the Hort Innovation banana research and development levy, co-investment from the Queensland Government Department of Agriculture and Fisheries, New South Wales Department of Primary industries and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture.

Preparing for cyclones

Have a plan for your farm this cyclone season

The monsoon in its active phase brings significant rainfall, heightened cyclone activity, and potential flooding risks to northern Australia, creating challenging conditions for growers. While many banana growers are experienced in managing such weather, it’s always a good idea to review and update action plans to stay prepared for potential cyclones.

The following information runs through pre-and-post-cyclone management options and mainly focuses on the effects of canopy removal of unbunched plants before the cyclone hits, and the impact of staggering the return to cropping on the subsequent fruit supply. The management options were investigated as part of an industry project in 2011/12 and remain current

What to consider when preparing for tropical cyclones

Bananas are very prone to wind damage and losses can be severe, even with low-category cyclones or severe thunderstorms. The likelihood of banana crop damage relates directly to wind strength, the wind resistance presented by a plant and the presence or absence of a bunch.

Pre-and-post-cyclone management options were investigated in 2011/12 in an industry project, which looked at the effects of canopy removal of unbunched plants before the cyclone hits, and the impact of staggering the return to cropping on the subsequent fruit supply.

Step 1 — looking at your blocks

The first step is to develop a clear idea of the stage of development of the blocks on the farm. How many blocks are plant crops, early ratoons or nurse-suckered, all of which will be more uniform than older ratoons. Of the more uniform blocks, identify those which are heavily bunched, those where the bulk of plants are close to bunching (within 4-6 weeks) and those which are about 2-3 months from bunching.

The uniform unbunched blocks offer the best opportunity to efficiently apply techniques like canopy removal rather than older ratoon blocks.

Step 2 — deciding whether to remove the canopy

The next step is to decide which blocks are most appropriate for treatments like canopy removal, which depends not only on the plant development stage but also the likely wind strength.

With any cyclone the bunched and large unbunched banana plants are most at risk, so strategies to reduce the wind resistance of these plants can help reduce the damage.

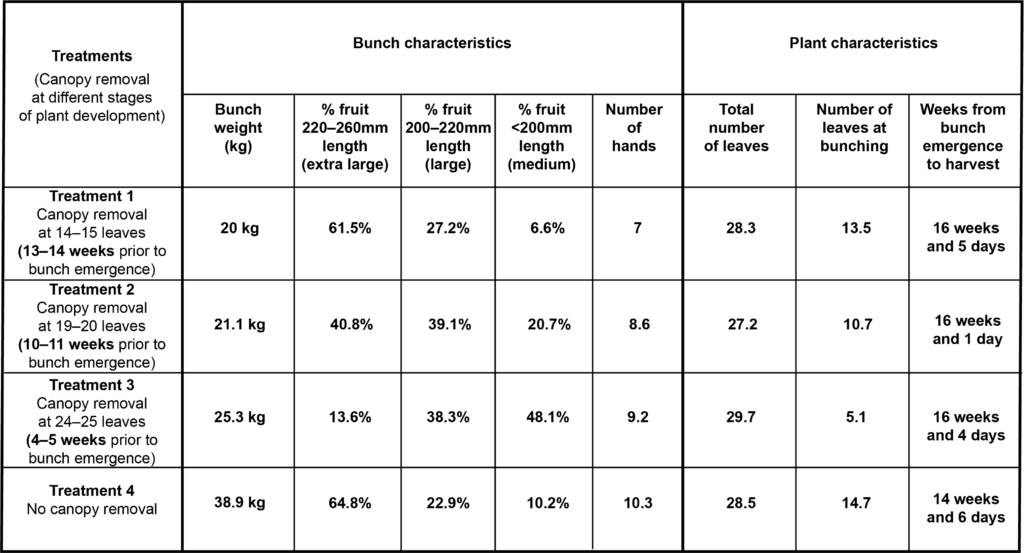

Canopy removal of unbunched plants prior to the cyclone helps to reduce the incidence of plants rolling out and can provide early bunch production. However, removing the canopy has major impacts on yield and fruit length, with 35- 50% reductions in bunch weight and 20-35% reductions in proportion of fruit in the extra large (220-260mm) fruit category (Table 1). Reductions in fruit length were most pronounced in the plants closest to bunching (4-5 weeks) while the biggest reductions in bunch weight occurred for plants that were 13-14 weeks from bunching.

Therefore a fair degree of certainty of damage is needed before embarking on canopy removal on a large scale. For a low-category or physically small cyclone, often the decision to remove the canopy is best left to the latest practical time possible.

Step 3 – how to cut if removing canopy

The way the canopy is removed is also important. ‘Full deleafing’ where the stem was not cut, resulted in a stronger stem that was better able to support a subsequent bunch compared to plants that had been cut through well below the ‘throat’ of the plant. See figures 2 and 3.

Results — canopy removal by 'full deleafing' of unbunched plants

Table 1 Bunch and plant characteristics for the canopy removal treatments

More information...

For important information on minimising the spread of Panama disease during and after a cyclone event refer to the ABGC fact sheet.

Contact our team:

The Better Bananas team

Department of Agriculture and Fisheries

South Johnstone

07 4220 4177 or email betterbananas@daf.qld.gov.au

Horticulture Innovation Australia (Hort Innovation) and the Queensland Government make no representations and expressly disclaim all warranties (to the extent permitted by law) about the accuracy, completeness, or currency of information in this factsheet. Reliance on any information provided by Hort Innovation and the Queensland Government is entirely at your own risk. Hort Innovation and the Queensland Government are not responsible for, and will not be liable for, any loss, damage, claim, expense, cost (including legal costs) or other liability arising in any way (including from Hort Innovation and the Queensland Government or any other person’s negligence or otherwise) from your use or non-use of this factsheet or from reliance on information contained in the material or that Hort Innovation and the Queensland Government provides to you by any other means.

Innovation opportunity for Western Australian banana growers

Would $6000 help if you had:

- A hunch you would like to explore in your banana production system?

- A great idea you would like to try out in your banana crop or in your packing shed?

- An ambitious R&D concept for bananas that you’d like to develop further?

An opportunity exists for Western Australian (WA) growers to apply for a grant. The grant is offered as part of the National Banana Development and Extension Program and would support the successful recipient to undertake a small innovative trial on their farm.

The Australian Banana Growers Council and the Department of Agriculture and Fisheries are looking for brief proposals for small innovation trials which can be conducted in 2021 or 2022. In this first round of grants, the extension team would like to explore great ideas with WA growers that could lead to big advances locally and for the national banana industry.

Using the one-page application form, tell us:

- What are the benefits to banana growers in WA.

What resources you would need to run the innovation trial:

– Time – how long would it take (Trials need to be completed by mid-March 2022*).

– Who would be involved and what are their skills e.g. myself (20 years banana farming experience) with support from the local agronomist. If you are aware of an individual with suitable skills that would be helpful, please nominate them on the form.

– What operating funds you will need to cover cost of supplies and services.

Proposals must be submitted by Friday, 12 March 2021 to Robert Mayers to be considered by the WA innovation grant panel. Proposals will be compared on the basis of their innovativeness and the potential for significant gains in your production system and the industry.

Your proposal should be brief and your budget below $6000. Be sure to include your full contact details. We plan to announce the successful proposal by the end of March 2021 and sign off on contracts in early April 2021.

The trial will need to be completed by mid-March 2022. Assistance is available to compile a trial report which will need to be sent to ABGC by 31 March 2022.

For further information or assistance putting your application together please don’t hesitate to contact:

Robert Mayers – Robert.Mayers@daf.qld.gov.au or 0467 960 412.

*Please let us know if you have an innovative idea that would take longer than a year to investigate.

This initiative is part of the National Banana Development and Extension Program (BA19004) and is facilitated by the Australian Banana Growers Council. This project has been funded by Hort Innovation, using the Hort Innovation banana research and development levy, co-investment from the Queensland Government Department of Agriculture and Fisheries, New South Wales Department of Primary Industries, and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture.

Past events

Past events...

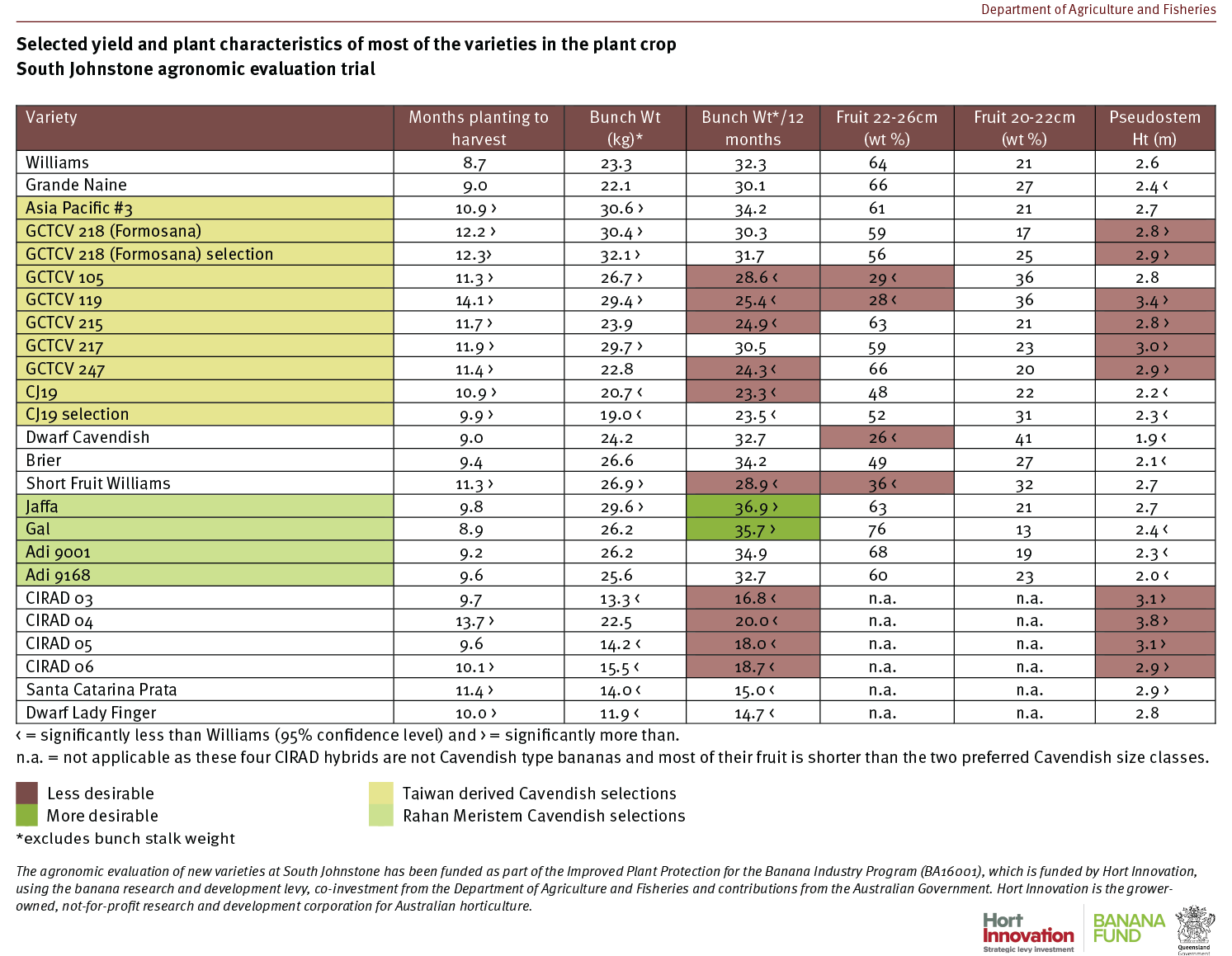

Yield and plant characteristics of plant crop

South Johnstone agronomic evaluations

Plant crop evaluation—Yield and plant characteristics

- « Previous Page

- 1

- …

- 7

- 8

- 9

- 10

- 11

- …

- 17

- Next Page »