Grower case study

Reinventing the pod into a footbath

Steps to help protect your farm from Panama disease don’t need to cost big dollars. There are some great examples of innovative and cost-effective solutions that banana growers have implemented to help manage their biosecurity risk. Something as simple as cutting down a 1000 litre pod to use as a footbath can be a big saving. The banana extension team recently had a chat with a grower about why he uses a pod.

The grower said that he purchased the pod as they are easy to come by with most of the fungicides applied by the aerial operators coming in 1000 litre pods.

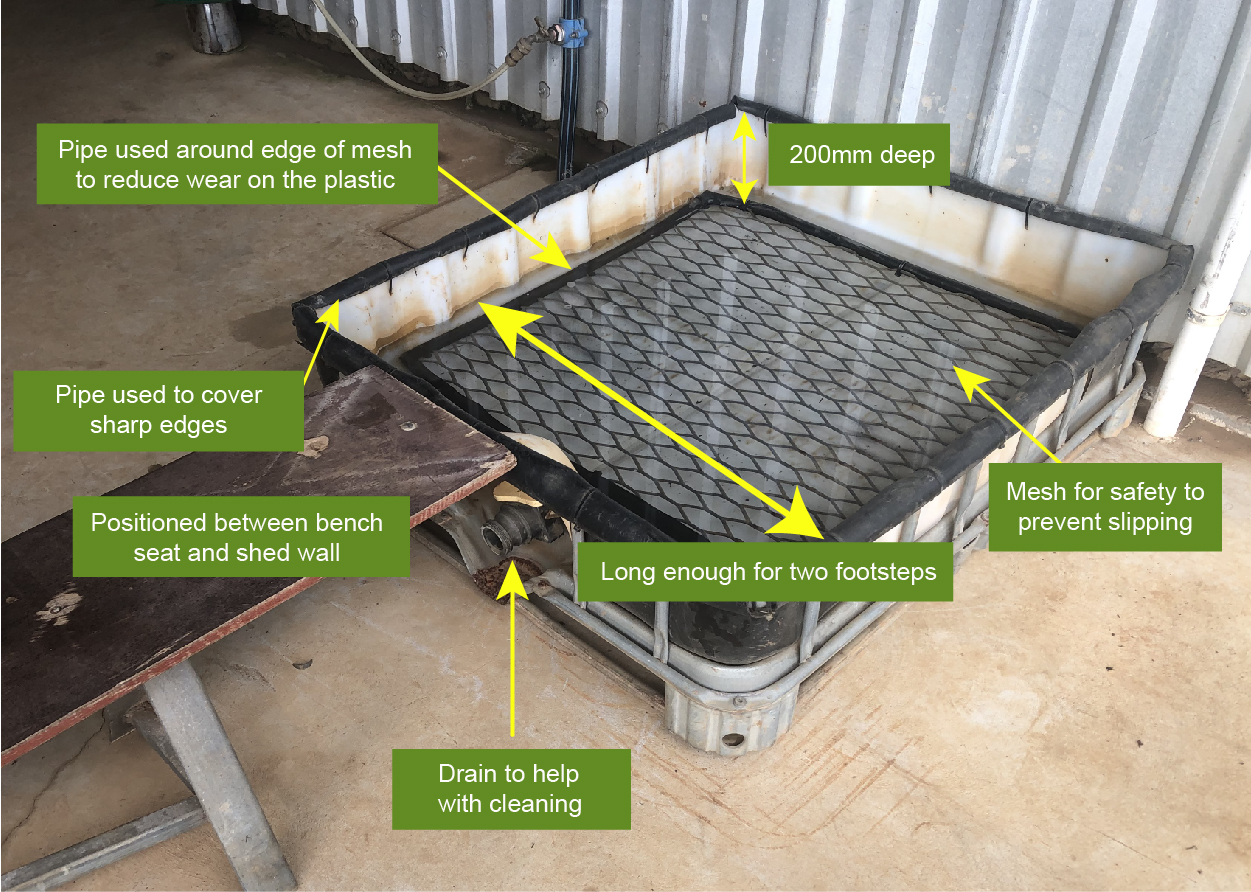

‘We cut the supporting frame and the plastic liner down to 200 mm, the same as a normal step, so it was easy to step in and out of,’ the grower said. ‘We then placed a piece of expanded mesh in the bottom of the pod, mainly to prevent anyone slipping’, said the grower. ‘When we started using the pod as a footbath, we found that we had to protect the pod from the mesh with irrigation pipe so that it wouldn’t wear a hole in the plastic. We also put pipe on the edge of the pod to cover any sharp edges,’ the grower explained.

Positioning of any footbath is important. When you walk into the shed the pod is located between a shed wall and the bench seat where you change shoes before walking through the footbath. ‘The pod is also good as it is long enough and wide enough that it is difficult to step over and you need to put both feet in,’ the grower said. There are also signs to direct people to use the footbath.

‘Another point with using a pod is that it comes with a built-in valve, making it easy to drain and clean. If we want to shift the pod for cleaning, we can do that with our forklift,’ said the grower.

Overall, the grower said, ‘We have found that if you make biosecurity easy to do, practices will be followed’.

Thank you to the banana grower who provided his time and gave permission to use this case study for the benefit of the wider industry.

Tips on disinfectants!

Use disinfectant products containing Didecyl dimethyl ammonium chloride (DDAC) or Benzalkonium chloride (BZK). These quaternary ammonium (QA) compounds have been tested and solutions mixed as per the label rate do kill the fungal spores that cause Panama disease.

It is important to remove all soil and organic matter before applying any disinfectant product.

Easy-to-use test strips can be used to regularly test QA concentration of solutions in footbaths, spray shuttles and wash-down facilities.

Click here for information on disinfectants.

If you would like further information or assistance with setting up or improving biosecurity practices for your farm, please contact the National Banana Development and Extension Team on email betterbananas@daf.qld.gov.au or phone 07 4220 4152.

This case study has been produced as part of project BA19004 the National Banana Development and Extension Program which is funded by Hort Innovation, using the banana industry research and development levies, co-investment from the Department of Agriculture and Fisheries and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture.