Volume and timing trials for bunch protection

About the trials

Volume and timing trials for bell injection and bunch spraying were conducted by the DPI extension team, after some growers expressed concern of not achieving adequate control of bunch pests.

Several trials have been completed to confirm and compare efficacy of registered chemistries as well as gain a better understanding of the importance of volume, coverage and timing of application.

The trials at the South Johnstone Research Facility in Far North Queensland looked at the effects of different treatments on the level of damage caused by the three main banana bunch pests treated via bell injection and bunch spraying.

Key findings

Banana scab moth

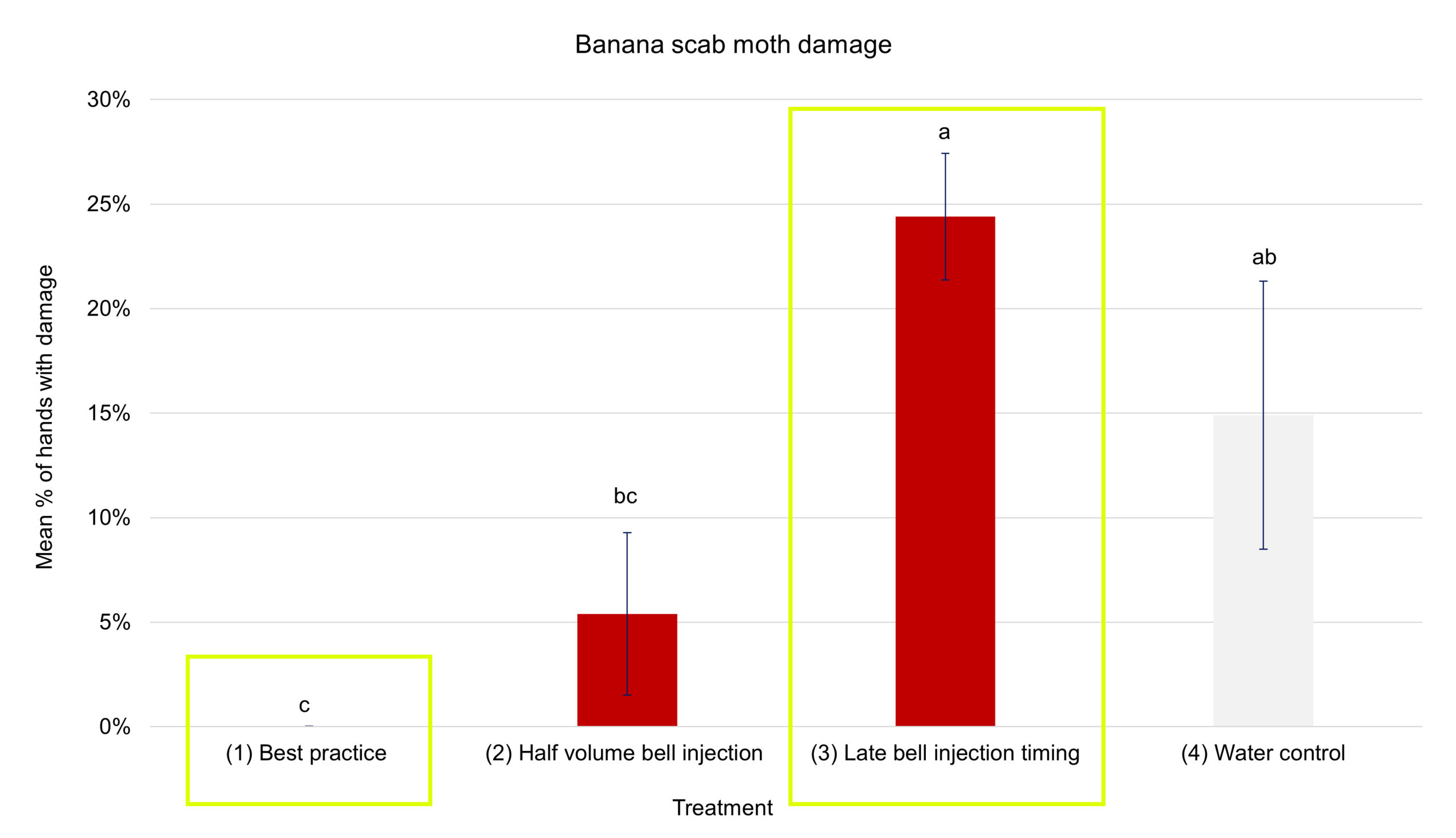

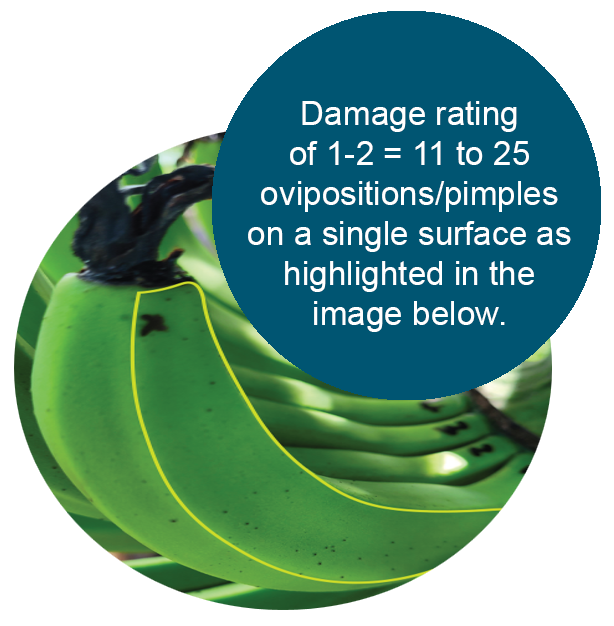

- Inject bells in the upright position. Bells injected late in the horizontal position had significantly more banana scab moth damage (nearly 25% of hands) compared to the best practice treatment that had no damage. See figure 1 below. The image carousel below shows the two timing treatments used in the trial.

- This trial also demonstrated that coverage is important. The best practice treatment of injecting bells in the upright position with full volume was the only treatment that was significantly less than the water control.

Banana flower thrips

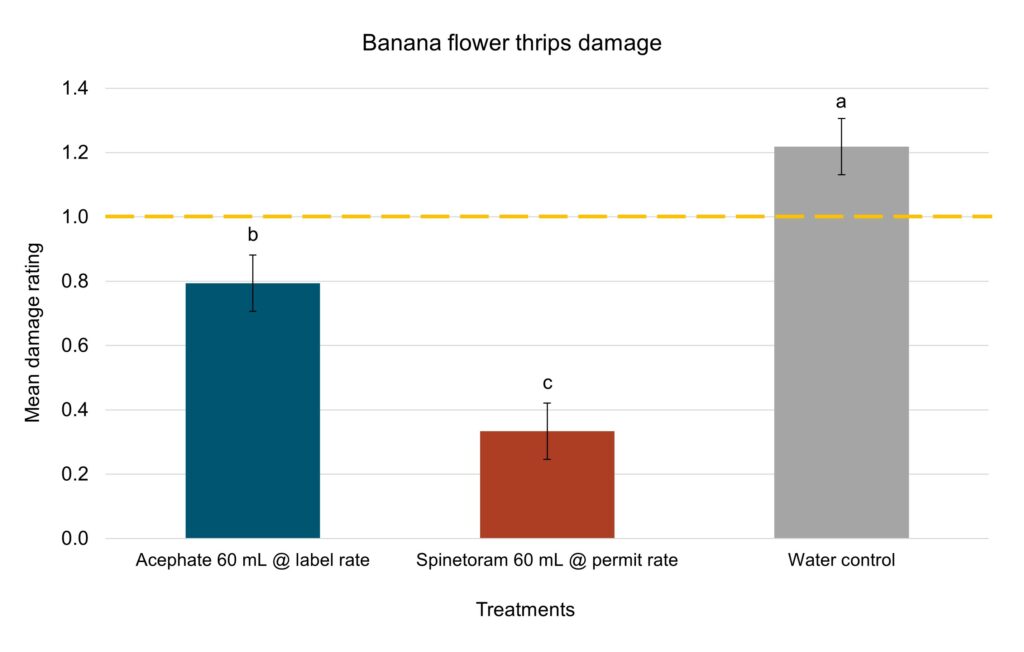

- Bell injecting with 60mL volume at permitted rates provided good control of banana flower thrips. Initial work found that bell injecting with acephate at 40mL volume @ label rate did not provide good control of banana flower thrips. Subsequent trials found good control was achieved by increasing the volume to 60mL @ label rate.

- Bell injecting with 60mL of either acephate or spinetoram at permitted rates provided good control of banana flower thrips. Bells injected with spinetoram had significantly less damage compared to bells injected with acephate at label rates. However, acephate still provided acceptable control at the 60mL volume, below the mean damage threshold of 1. See Figure 2 below.

Banana rust thrips

- Multiple trials using 50-60mL of spinetoram solution as a bunch spray has consistently achieved good control of banana rust thrips. Note, this is in combination with bell injecting with acephate solution.

- Both air assisted and hydraulic systems have been effective in providing effective coverage required for control.

- Trial assessments of banana rust thrips damage were undertaken on mature fruit at harvest.

- In accordance with the label, bunches were sprayed with spinetoram solution after the bunch cover was applied.

Tips!

Always use registered products in accordance with the label and check rates and volumes before use.

Regularly check and calibrate equipment to ensure effective application and safety.

Good even coverage is important for effective control.

Mix insecticide solutions well and use spinetoram solution within 72 hours of being mixed.

Reminder! There is a permit (PER87198) for bell injection with spinetoram and the rate is different to the rate used for bunch spraying as per the product label.

More information:

DPI Banana Extension Team

Department of Primary Industries

South Johnstone

13 25 23 or email betterbananas@dpi.qld.gov.au

This research has been undertaken as part of the National Banana Development and Extension Program (BA19004), which is funded by Hort Innovation, using the banana industry research and development levies and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. The Queensland Government has also co-funded the project through the Department of Primary Industries.

Horticulture Innovation Australia (Hort Innovation) and the Queensland Government make no representations and expressly disclaim all warranties (to the extent permitted by law) about the accuracy, completeness, or currency of information in this factsheet. Reliance on any information provided by Hort Innovation and the Queensland Government is entirely at your own risk. Hort Innovation and the Queensland Government are not responsible for, and will not be liable for, any loss, damage, claim, expense, cost (including legal costs) or other liability arising in any way (including from Hort Innovation and the Queensland Government or any other person’s negligence or otherwise) from your use or non-use of this factsheet or from reliance on information contained in the material or that Hort Innovation and the Queensland Government provides to you by any other means.