Bunch spray technology trial

About the trial

To support growers transition from bunch dusting to bunch spraying, the DPI extension team have investigated alternative bunch spray systems that deliver good coverage for controlling banana rust thrips.

The trial consisted of three different air assisted systems and three different hydraulic systems, comparing their effectiveness in achieving adequate coverage of insecticide solution, required for controlling banana rust thrips. Bells were injected with a 60mL volume of acephate solution and liners and bunch covers were tied with flues (opening left in top of bag). As per the label, 50-60mL of spinetoram solution was applied to bunches after the liner and bunch cover had been placed on the bunch.

Assessments for banana rust thrips damage was undertaken at harvest, with all fingers in a bunch assessed for damage.

Hydraulic systems - delivering 28psi with 12v pump

Treatment 1 – Spray wand from underneath the bag

Teejet grey adjustable nozzle (38720-PPB-X8)

Spray applied from underneath the bunch cover and liner. Spraying from the top hand to the bottom in a zig-zag motion for 5-6 seconds.

Treatment 2 – Spray wand from underneath and top of bag

Teejet grey adjustable nozzle (38720-PPB-X8)

Spray applied via the flue at the top of the bunch cover for 2 seconds. Then applied underneath the bunch cover and liner from top hand to the bottom in a zig-zag motion for 3-4 seconds.

Treatment 3 – Spray ring prototype

3 x 0.75 (BETE FF028-145) nozzles

Ring was slid underneath the liner and bunch cover and spray was applied from top hand to bottom hand for 3-3.5 seconds. *Note, the ring was difficult to get up underneath the liner and bunch cover and was not easy to use or time efficient.

Air-assisted systems - delivering 28psi with 12v air compressor

Treatment 4 – Aeropro spray gun

2.5mm nozzle opened half of a turn

Spray applied from reaching under the bunch cover and liner, spraying up at a 45-degree angle as far around the bunch and down to the bottom hands in a zig zag motion for 5-6 seconds.

Treatment 5 – Star S-770 spray gun

1.2mm nozzle opened one and a half turns

Spray applied from reaching under the bunch cover and liner, spraying up at a 45-degree angle as far around the bunch and down to the bottom hands in a zig-zag motion for 4-5 seconds.

Treatment 6 – Prototype air sprayer

using 12v air compressor and 12v pump

Spray applied from just underneath the bunch cover and liner, spraying from the bottom of the bag pointing upwards for 3-3.5 seconds.

Key findings

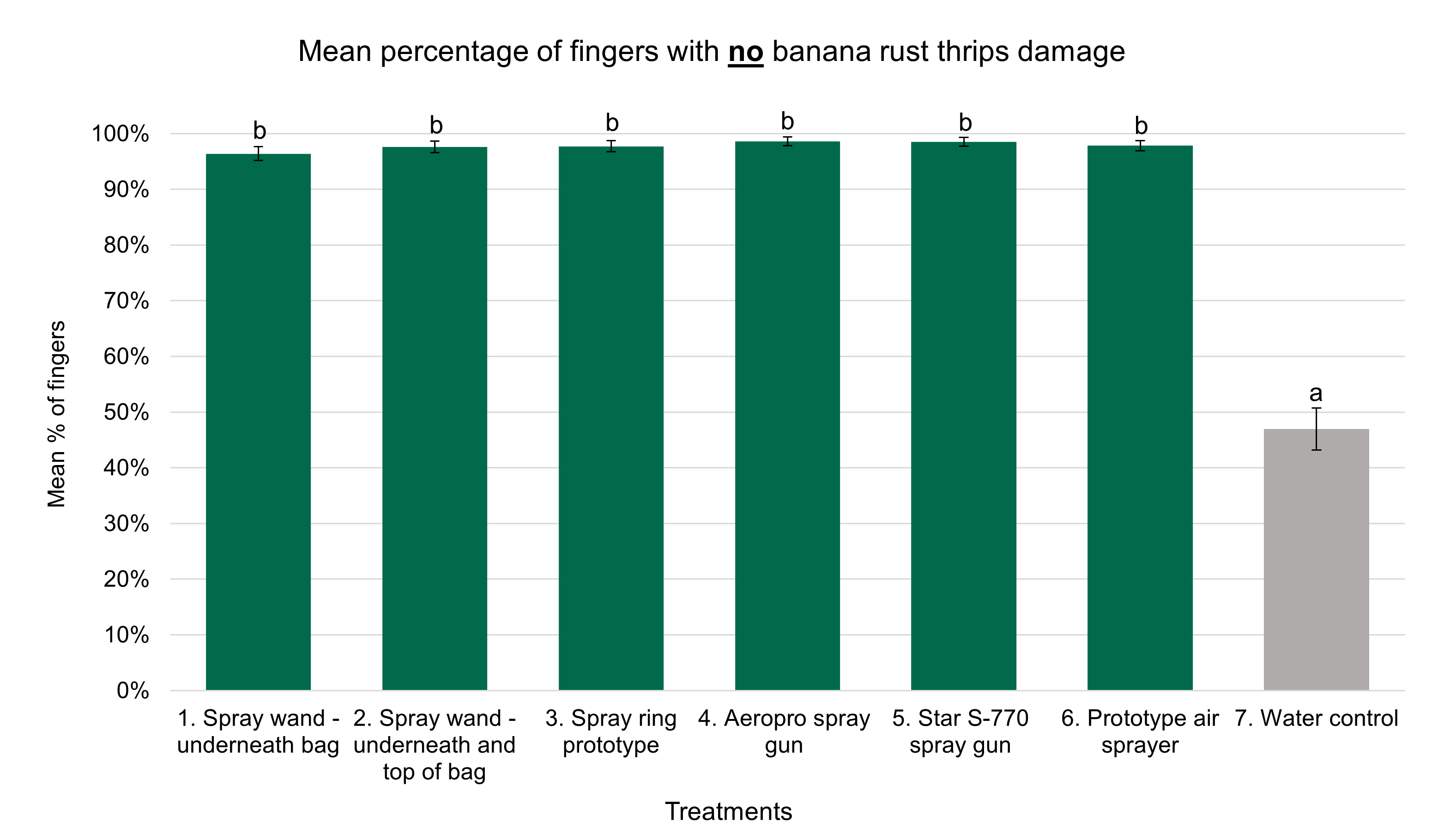

All air-assist and hydraulic chemical spray treatments provided good control of banana rust thrips (Figure 1).

Greater than 96% of all fingers in bunches across all treatments recorded no damage. This compared to 47% of fingers in the water control.

Positioning the spray ring (treatment 3) underneath the liner and bunch cover was difficult and the time taken would not make it commercially feasible.

Growers that have previously dusted can easily modify their current compressed air system to trial the air-assisted options.

The DPI extension team in collaboration with banana grower Mark McAvoy put together a demonstration video of the spray gun system Mark uses on his farm for bunch spraying.

More information:

The DPI Banana Extension Team

Department of Primary Industries

South Johnstone

13 25 23 or email betterbananas@dpi.qld.gov.au

This research has been undertaken as part of the National Banana Development and Extension Program (BA19004), which is funded by Hort Innovation, using the banana industry research and development levies and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. The Queensland Government has also co-funded the project through the Department of Primary Industries.

Horticulture Innovation Australia (Hort Innovation) and the Queensland Government make no representations and expressly disclaim all warranties (to the extent permitted by law) about the accuracy, completeness, or currency of information in this factsheet. Reliance on any information provided by Hort Innovation and the Queensland Government is entirely at your own risk. Hort Innovation and the Queensland Government are not responsible for, and will not be liable for, any loss, damage, claim, expense, cost (including legal costs) or other liability arising in any way (including from Hort Innovation and the Queensland Government or any other person’s negligence or otherwise) from your use or non-use of this factsheet or from reliance on information contained in the material or that Hort Innovation and the Queensland Government provides to you by any other means.